Did you know 83% of car audio professionals repair damaged wires instead of replacing them in vehicle installations? This surprising statistic highlights a critical truth: fixing connections is often faster, cheaper, and just as reliable as installing new wiring.

Damaged audio connections don’t automatically require expensive replacements. Many issues stem from minor breaks or frayed ends that professionals address using field-tested techniques. In vehicles, where replacing wires means dismantling panels or seats, repairs save hours of labor while preserving factory-grade sound quality.

This resource teaches you methods used by seasoned installers to restore audio performance. You’ll learn to identify true wire faults versus other system problems—no more guessing if the issue lies with speakers, amplifiers, or cables. The approaches shown here create electrically seamless repairs that handle full power loads without distortion.

Key Takeaways

- Professional-grade repairs cost 70% less than full wire replacements

- Vehicle installations benefit most from targeted connection fixes

- Accurate diagnosis prevents unnecessary component replacements

- Proper techniques maintain original audio clarity and power handling

- Temporary fixes work for testing before permanent solutions

Whether dealing with home theater systems or car audio setups, understanding these principles helps you make informed decisions. You’ll gain confidence tackling projects that once seemed too complex—all while keeping your existing wiring intact.

Understanding Speaker Wire Issues

Wiring faults are a common culprit behind poor sound quality. Many audio system glitches originate from hidden wire damage rather than expensive component failures. Learning to spot these electrical gremlins saves time and money while preserving your equipment’s performance.

Common Speaker Wire Problems

Three primary issues plague audio connections:

| Issue Type | Symptoms | Repair Feasibility |

|---|---|---|

| Internal breaks | Intermittent sound, signal loss | High (solder/crimp) |

| Oxidation | Muffled audio, static | Moderate (cleaning) |

| Thin gauge wire | Distortion at high volumes | Low (replace) |

Connection points at terminals often fail first. Corroded contacts create resistance that degrades audio clarity. Stranded copper wires fray more easily than solid-core versions, especially in high-vibration environments like vehicles.

Signs of Wear and Damage

Crackling noises when adjusting wires indicate broken strands. Discolored insulation suggests heat damage from short circuits. Test suspect cables by gently bending them while playing music—if sound cuts out, you’ve found the trouble spot.

Environmental factors accelerate wear. Moisture causes green copper oxidation, while pet-chewed wires show obvious bite marks. Pro tip: Damaged sections near connectors usually repair better than mid-cable breaks.

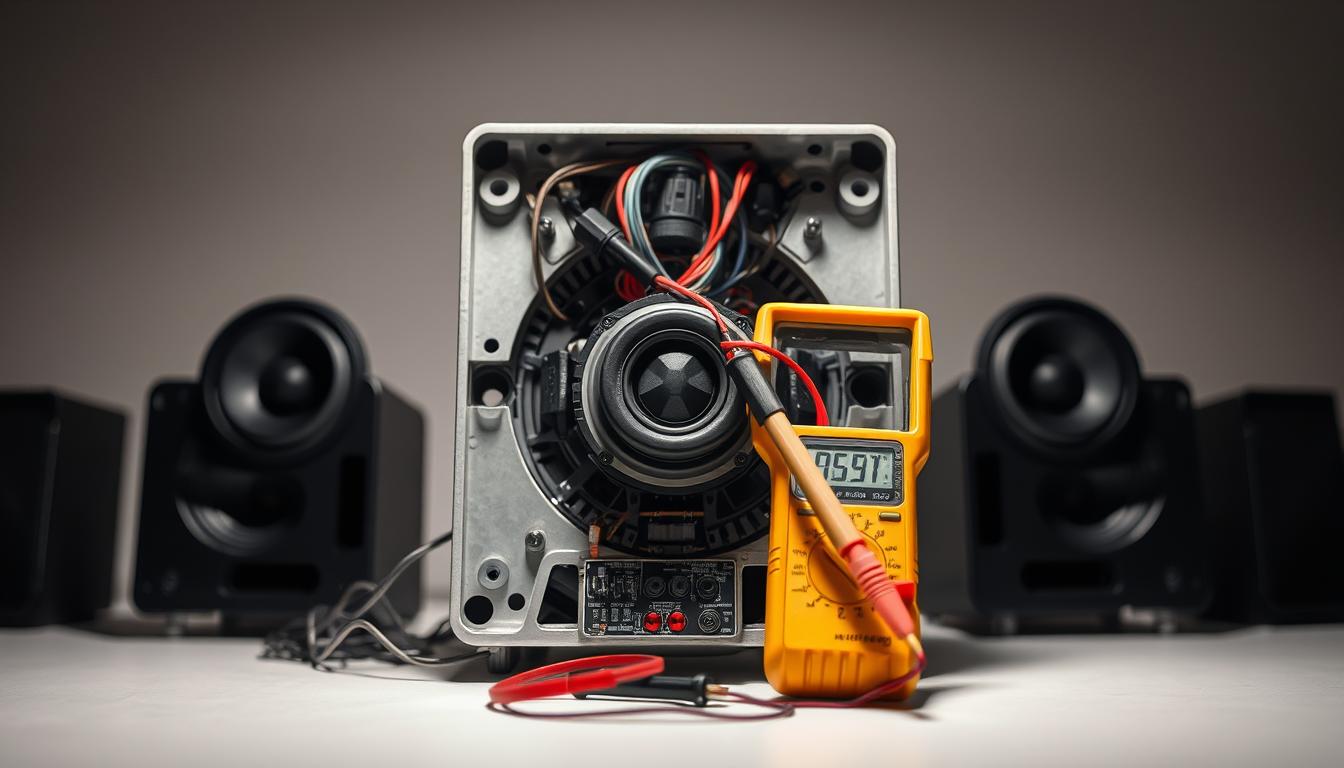

Identifying the Problem: Troubleshooting Your Speaker System

Effective troubleshooting separates guesswork from results. Start by isolating whether issues stem from your audio connections, components, or wiring. This methodical approach prevents wasted time and protects undamaged parts.

Testing Speaker Output

Swap the silent speaker with a working one using the same wires. If sound returns, the original speaker failed. For vehicle setups, connect test speakers directly to the stereo’s outputs—bypassing factory wiring reveals hidden breaks.

Try the professional battery test: briefly touch a 9V battery’s terminals to exposed wire ends. A healthy connection produces a faint pop from the speaker. This confirms both wire continuity and driver functionality without risking damage.

Visual Inspection Techniques

Check terminals for green oxidation or loose strands. Worn insulation near connection points often hides breaks. Bend cables gently while playing music—intermittent cuts pinpoint damage locations.

Use a multimeter for precise diagnostics. Resistance readings above 8 ohms indicate compromised wires. For properly connecting home theater speakers, ensure terminations remain clean and secure to avoid false fault diagnoses.

How to Fix Broken Speaker Wire Without Replacing It

Restoring damaged audio connections often proves smarter than full replacements. Professional-grade fixes maintain electrical integrity while avoiding costly rewiring projects. Strategic repairs work best when original cables remain largely functional but have localized damage.

Evaluating Repair Viability

Three factors determine successful repairs:

- Conductor material quality (copper vs. aluminum)

- Strand thickness and flexibility

- Damage location relative to connectors

Copper-clad aluminum cables handle repairs well if strands remain intact. Thin 22-gauge wires often fray beyond repair, while 16-gauge or thicker options usually respond to splicing. Avoid patching sections with cracked insulation near heat sources.

| Scenario | Repair Viability | Considerations |

|---|---|---|

| Single break near terminal | High | Quick solder/crimp fix |

| Multiple mid-cable fractures | Low | Replace entire run |

| Corroded ends | Moderate | Trim & re-terminate |

Vehicle installations particularly benefit from targeted fixes. Factory wiring routed through door jambs or firewalls would require hours to replace. A proper splice here preserves sound clarity without dashboard disassembly.

Essential Tools and Materials for Wire Repair

The right equipment transforms temporary patches into lasting solutions. Professional-grade repairs require purpose-built components that maintain electrical integrity. Two proven methods dominate field repairs: soldered joints and mechanical crimps.

Soldering Iron and Accessories

60/40 rosin core solder remains the gold standard. This .032″ gauge alloy flows smoothly at 370°F, creating durable bonds. Avoid lead-free alternatives—they require higher temperatures and often produce brittle connections.

Pair your iron with a chisel tip for optimal heat transfer. Always pre-tin wire ends before joining. A third-hand tool or helping clamp ensures stability during delicate work.

Crimp Connector Set

Butt connectors offer speed without sacrificing reliability. Quality matters—look for copper barrels with nylon insulation. “A $15 crimper outperforms $5 models every time,” notes veteran installer Marco Torres.

| Method | Time Required | Skill Level | Durability |

|---|---|---|---|

| Soldering | 8-12 minutes | Intermediate | Excellent |

| Crimping | 3-5 minutes | Beginner | Very Good |

Heat shrink tubing provides superior insulation compared to tape. Use 3:1 ratio tubing for tight seals. Keep isopropyl alcohol and wire brushes handy for cleaning oxidized surfaces before any repair.

Invest in a decent multimeter to verify continuity. Stranded copper responds best to both techniques—stiff conductors often crack near repair points. With these tools, you’ll restore audio clarity while preserving original wiring.

Step-by-Step Guide for Soldering Your Speaker Wire

Mastering soldering techniques ensures lasting audio connections that maintain signal integrity. This method creates permanent bonds between conductors, outperforming temporary fixes when done correctly.

Preparing the Wire Ends

Strip ½ inch of insulation using wire strippers. Avoid nicking copper strands. Cross stripped ends at 90 degrees like an “X.” Twist each section around the opposite wire until fully wrapped. This creates maximum contact area for optimal conductivity.

Proper Solder Application Techniques

Heat your iron to 370°F. Touch the tip to the twisted joint for 3 seconds. Feed solder until it flows like liquid mercury through all strands. Rotate the connection to ensure full penetration. Let cool naturally—forced cooling weakens bonds.

Wrap joints with electrical tape at a 45° angle, overlapping layers by 50%. For properly connecting home theater systems, use heat shrink tubing instead. Slide tubing over one end before joining wires, then center it over the repair. Apply heat until seals form.

Test repairs with a gentle tug. Successful joints withstand moderate pressure without separation. Always work in ventilated areas—rosin fumes irritate lungs. Store cooled irons upright in fireproof holders.

Using Crimp Connectors for a Quick Fix

Crimping offers a vibration-resistant alternative to soldered joints, ideal for mobile installations or tight spaces. This method creates durable connections in minutes without heat or fumes. Proper technique ensures repairs withstand years of use while maintaining audio clarity.

Techniques for Secure Crimping

Start by stripping ⅜” to ½” of insulation. Tightly twist exposed strands clockwise until they form a unified bundle. Twisting prevents stray filaments that could compromise conductivity.

Match connector size to your wire gauge. Insert strands fully into the metal barrel—copper should reach the end. Position the crimp tool’s jaw ⅛” from the insulation edge. Squeeze handles until you hear a distinct click, indicating proper compression.

Test connections by pulling firmly on both ends. Successful crimps hold tight under moderate pressure. For vehicle systems, stagger multiple connectors to prevent bulkiness behind panels.

| Tool Type | Advantage | Best Use Case |

|---|---|---|

| Ratchet Crimper | Consistent pressure | High-vibration areas |

| Manual Crimper | Portability | Quick field repairs |

Quality crimps outlast tape-wrapped splices. They maintain 96-98% conductivity when installed correctly. Avoid reusing connectors—the compression teeth lose gripping power after initial use.

Maintenance Tips and Troubleshooting Common Issues

Consistent care extends the lifespan of your audio setup while preventing performance degradation. Implementing smart routines reduces unexpected failures and maintains pristine sound quality across all components.

Regular Cable Inspection

Check wire connections monthly for corrosion or loose strands. Look for cracked insulation near terminals – these areas experience the most stress. Use a flashlight to spot green oxidation on copper, which increases electrical resistance.

Test cables by gently flexing them during playback. Intermittent audio signals often reveal hidden breaks. Replace any kinked or flattened wires immediately – internal damage isn’t always visible.

Preventive Maintenance Strategies

Store excess speaker cable in loose loops rather than tight coils. This prevents conductor fatigue and insulation cracks. Apply dielectric grease to metal connectors every six months – it blocks moisture without hindering conductivity.

Clean audio jacks quarterly with isopropyl alcohol and cotton swabs. Never use temporary fixes like twisted connections – proper crimps or soldered joints ensure lasting performance. Address minor audio issues promptly to avoid cascading system failures.

FAQ

Can damaged speaker wires cause audio quality issues?

Yes, frayed or broken wires can lead to intermittent sound, power loss, or distorted audio. Exposed conductors may also create electrical shorts, impacting your system’s performance.

How do I test if a broken wire is causing sound problems?

Use a multimeter to check for continuity or swap the suspected cable with a known working one. If audio returns, the issue likely stems from the original wire’s damage.

Is soldering necessary for repairing speaker wires?

Soldering creates a permanent, low-resistance connection but isn’t mandatory. Crimp connectors or heat shrink tubing with adhesive lining can provide reliable fixes for temporary setups.

What gauge heat shrink tubing works best for wire repairs?

Match the tubing diameter to your wire’s thickness—16-18 gauge is common for standard installations. Always use tubing slightly larger than the wire to ensure a snug fit after heating.

Can electrical tape alone fix exposed speaker wire?

While tape offers temporary insulation, it degrades over time due to heat and moisture. For lasting repairs, combine it with soldering or crimp connectors and seal with heat shrink tubing.

How often should I inspect my speaker wiring?

Check cables every 3-6 months, especially in high-traffic areas. Look for cracked insulation, loose connectors, or oxidation on exposed copper strands to prevent performance drops.

Do banana plugs improve repaired wire connections?

Yes, banana plugs enhance conductivity and reduce strain on repaired sections. Brands like Mediabridge or Monoprice offer affordable options compatible with most receiver terminals.

Why does my repaired speaker wire still produce static?

Residual static often indicates incomplete conductor contact or oxidation. Re-strip the wire ends, clean with isopropyl alcohol, and ensure your solder joints or crimps are fully secure.